Controlled Potential Coulometry for Plutonium Assay

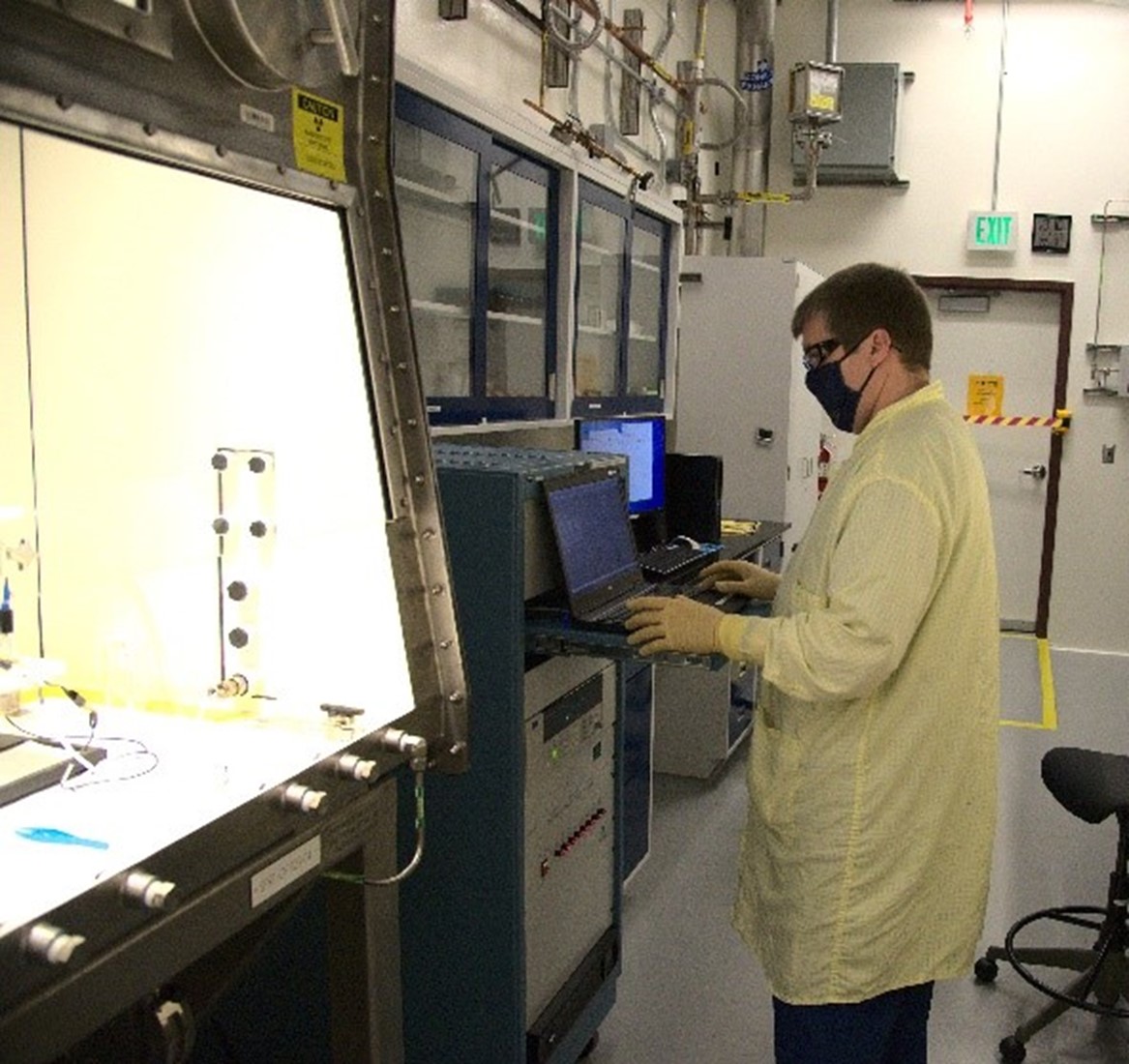

Los Alamos scientist using the newly installed CPC system in RLUOB.

Controlled Potential Coulometry for Plutonium Assay

Los Alamos National Laboratory’s Actinide Analytical Chemistry group’s (C-AAC) controlled potential coulometric (CPC) plutonium assay method fills an important role for many programs of both national and international importance. As part of the Department of Energy (DOE) nuclear facilities upgrade process and in support of NNSA’s Plutonium Production Program, C-AAC is moving into new laboratory space at TA-55’s Radiological Laboratory Utility Office Building (RLUOB). In collaboration with Savannah River National Laboratory (SRNL), a new coulometer has been installed and made ready at the new laboratory space at the RLUOB. The new instrument has now begun the qualification and validation process to become war reserve- and ISO17025-certified while software modernization and user interface improvement is ongoing.

The controlled potential coulometric plutonium assay method is a primary tool for material control and accountability and executes work in all of DOE’s missions: national security, science, control and accountability. In addition, CPC assay is used to certify the standards used by DOE programs in defense, nonproliferation and nuclear accountability/safeguards, counter-proliferation, nuclear materials technologies, and basic science. Many non-destructive assay instruments used throughout the DOE complex are calibrated with matrix matched standards that were standardized against assays provided by the CPC method.

Since the early 1970s, Los Alamos had used a custom CPC system implementing PAR 173 technology. In the early 1980s SRNL sought a commercially available CPC system, but could not find one that provided sufficient stability, precision and accuracy to certify plutonium reference standards and meet the needs of plutonium production and research. SRNL met this need by designing and building a custom CPC system. This first-generation SRS coulometer is based on the DOE-NBL coulometer, developed by the research team of Holland, Frazzini, Weiss and Pietri at what is now the NBL Program Office. This system rapidly gained international recognition and was adopted by several organizations including the International Atomic Energy Agency (IAEA). SRNL developed its first production coulometer in 1985, building on the work at NBL. SRNL built two coulometers for NBL in the mid-1990s that NBL used to certify CRM-126A.

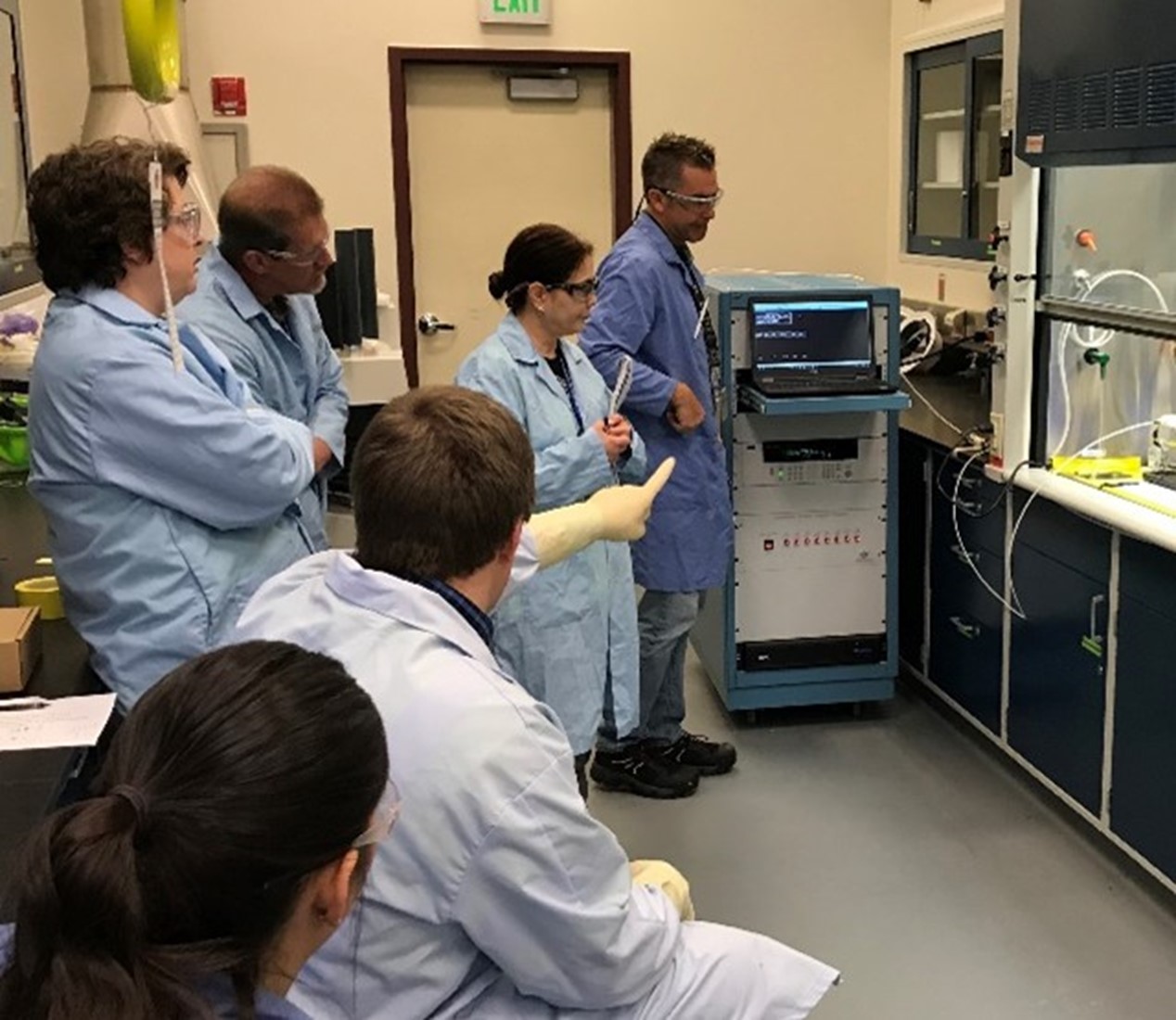

Upgraded SRNL CPC system in the Laboratory RLUOB in 2019. Los Alamos and SRNL personnel are completing the install and testing the equipment.

Upgraded SRNL CPC system in the Laboratory RLUOB in 2019. Los Alamos and SRNL personnel are completing the install and testing the equipment.In 2009, the IAEA and SRNL realized that there were no longer parts for the 1980 (model 1) SRNL design, and Los Alamos analysts realized the old PAR173-based system that had been the workhorse of the Plutonium Assay team since the early 1970s also lacked available replacement parts. SRNL, with funding and input from analysts at all three laboratories (SRNL, Los Alamos and the IAEA), embarked on a total redesign and upgrade of the SRNL system. In 2010-2011, the first three systems were installed at SRNL, IAEA and Los Alamos. The system installed at the Los Alamos Chemistry and Metallurgy Research Facility was both ISO17025 certified and war reserve certified and has been in constant use since 2012. The three labs compared results as part of the overall qualification process. Results obtained from the three laboratories agreed within 0.04%, which is within the margin of error for the measurement.

SRNL was contracted to build new coulometers for use in RLUOB. In 2019, SRNL personnel came to Los Alamos, assembled the system, trained analysts and monitored site acceptance testing. In 2021, SRNL returned to assemble a third instrument that had been delivered in 2020. In addition, they performed system checkups and calibrations for the existing Los Alamos systems. As part of this SRNL visit, method files were updated to analyze plutonium and match the existing qualified Los Alamos instrument.

Funding and Mission

The work is funded by Pu Modernization and it supports the pit production mission and the Materials for the Future Capability Pillar. LA-UR 22-23078